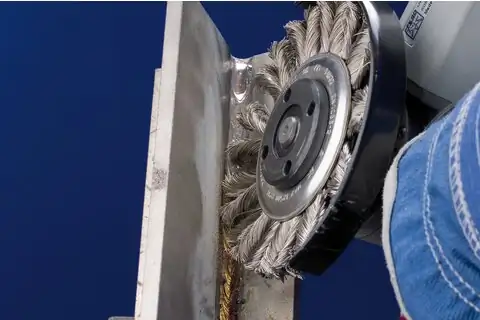

Wheel brushes knotted, COMBITWIST, INOX-TOTAL, with hole

COMBITWIST INOX-TOTAL wheel brush RBGIT dia. 115x12x22.2 mm stainless steel wire dia. 0.35 mm angle grinders

POS RBGIT 11512/22,2 CT INOX 0,35

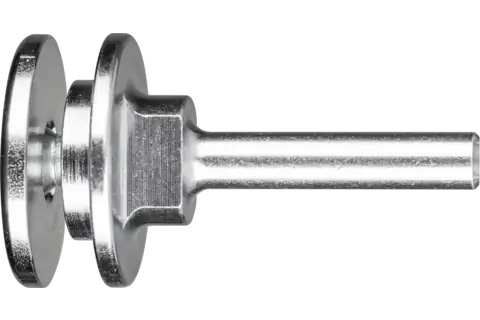

Matching accessories & spare parts

Technical information

COMBITWIST INOX-TOTAL wheel brush RBGIT dia. 115x12x22.2 mm stainless steel wire dia. 0.35 mm angle grinders

- Dia. external

- 115 mm

- Dia. filament material

- 0.35 mm

- Dia. hole

- 22.2 mm

- Filament material

- Stainless steel wire (INOX)

- Length, filament

- 22 mm

- Max. RPM

- 12500 RPM

- Mounting system

- Centre hole

- Number, knots

- 24 pcs.

- Packaging

- POS packaging

- RPM, optimum

- 5000 - 12500 RPM

- Width

- 12 mm

- Packaging unit

- 1 piece

Description

Special features

Recommendations for use

- Materials that can be worked

- Applications

- Drive types

PFERD TOOLS VALUE

PFERD TOOLS ERGONOMICS

recommends the COMBITWIST design to sustainably reduce the vibration produced during use and to improve comfort when working.