“We know no other way,” says Dr. Ina Terwey-Scheulen, Director Global Marketing, Product Management & PFERD TOOLS ACADEMY. She adds that there is a clear reason why the PFERD TOOLS claim is “Innovative by Tradition”. “The topics of innovation and continuous development of our tools, our tool range and the company are in our DNA.”

This drive for change is driven fundamentally by the cooperation with customers, as the director underlines. “We are often on site with our users. When we’re with them, we discuss their challenges and requirements and are constantly developing new ideas and approaches for application and tool solutions.”

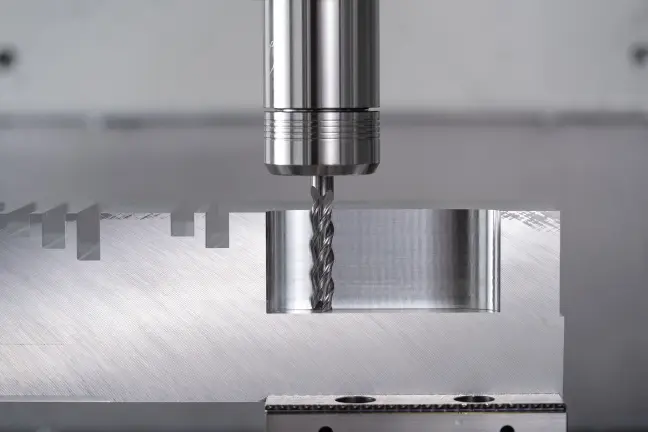

It is this combination of demand, PFERD TOOLS expertise and the desire to make further and new developments that fostered the idea of expanding the portfolio to include solid carbide tools (SCT) for machining on automated centres to complement the extensive range of tools for work on surfaces and cutting. “We see that these machining processes often pose problems for our customers and that they consistently want advice in these situations.”

This, in turn, is one of PFERD TOOLS’ core competencies, according to Terwey-Scheulen, and expanding the SCT range enables PFERD TOOLS to now provide an even more comprehensive service regarding the production processes of its users. “Our mission, first and foremost, is always to optimize processes, reduce costs and/or increase productivity.”

This is clearly appreciated by customers. The range of solid carbide tools now comprises almost 600 items, two material-optimized Performance lines for demanding applications when machining stainless materials and non-ferrous metals as well as a high-performance Universal line for milling and drilling. “And if our portfolio doesn’t contain the optimum solution, PFERD TOOLS offers what we call ‘customized innovation’ for these cases – custom solutions tailored to individual needs.”

All tools come from the PFERD TOOLS centres of expertise in Germany, Switzerland and Italy and are all made in Europe. “Our production facilities are state of the art and our machinery currently includes 93 ultramodern CNC tool grinding machines. Our services cover every stage involved in achieving the best possible tool solution – from tool preparation and in-house coating to post-treatment of the layer.”

Naturally, PFERD TOOLS is also looking to achieve growth of its own with the new portfolio of solid carbide tools for milling and drilling, Terwey-Scheulen adds. “On our journey to becoming the problem-solver for the process steps for work on surfaces, cutting and machining, this new portfolio has enabled us to make a huge step forwards, and our customers attest to this on a daily basis. As I’ve said – we simply know no other way!”

The new catalogue of solid carbide tools for milling and drilling is available on the homepage.

Version for trade media

Naturally, PFERD TOOLS is also looking to achieve growth together with retailers with the new portfolio of solid carbide tools for milling and drilling, Terwey-Scheulen adds. “For our trade partners, this will create additional sales potential among existing customers, plus key levers for generating business with new customers. On our shared journey to becoming the problem-solver for the process steps for work on surfaces, cutting and machining, this new portfolio has enabled us to make a huge step forwards, and our customers attest to this on a daily basis. As I’ve said – we simply know no other way!”

The new catalogue of solid carbide tools for milling and drilling is available on the homepage.