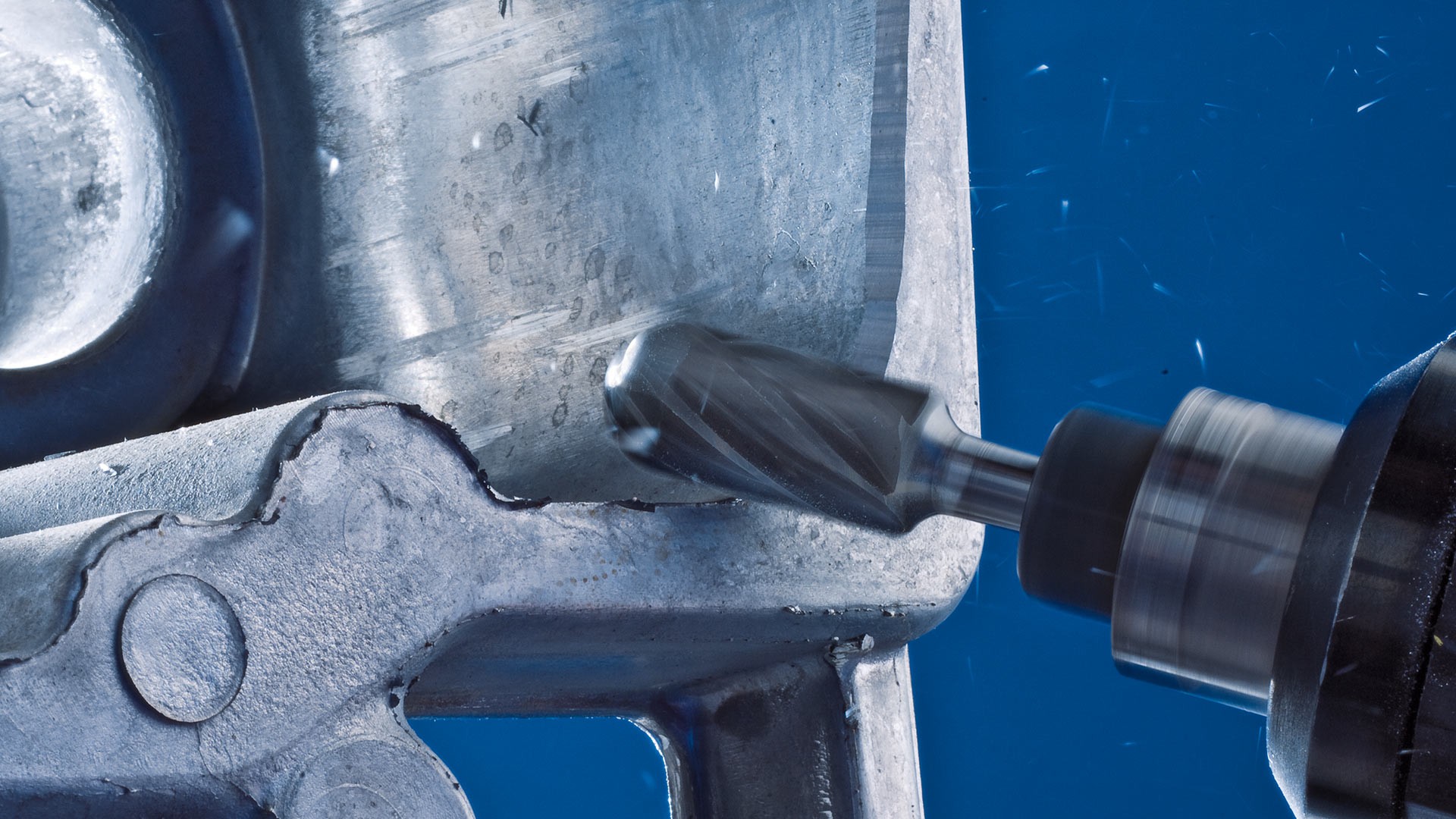

HICOAT coatings for burrs

PFERD TOOLS offers tungsten carbide burrs with HICOAT coatings to tackle particularly demanding applications.

The innovative protective coating from PFERD TOOLS enables you to work for long periods with low levels of fatigue, whilst saving resources and achieving perfect results as quickly as possible.

What does a HICOAT coating do?

The HICOAT coating acts as a separating layer between the cutting edge and the workpiece as well as chips. It protects the tool against friction, heat and abrasion, and also facilitates higher cutting speeds.

The harder surface as well as reduced friction prevent the adhesion of chips.

Which HICOAT coating is suitable for machining iron and steel materials?

The HICOAT coating HC-FEP is specifically designed for iron and steel materials. Tungsten carbide burrs with the HICOAT coating HC-FEP are characterized by a high degree of hardness and wear resistance.

The coating enables effective chip removal through improved anti-adhesion characteristics and is highly temperature-resistant. It allows for a longer tool life and use at higher cutting speeds in comparison with uncoated burrs. This means its performance is retained for longer.

Advantages:

- High hardness and wear resistance.

- Effective chip removal through improved anti-adhesion characteristics.

- Very high resistance against thermal load.

- Increased tool life.

- Also suitable for use at higher cutting speeds when compared with uncoated burrs.

Which HICOAT coating is suitable for machining aluminium alloys?

Aluminium alloys are soft and are easy to machine. With this material, only very low machining forces act upon the tool in comparison to steel with the same strength.

The HC-NFE HICOAT coating is recommended for long-chipping and lubricating aluminium alloys and non-ferrous metals.

The use of burrs with the PFERD TOOLS HICOAT coating HC-NFE prevents chips adhering and therefore the burr from clogging during work on soft aluminium alloys. This increases the tool life and improves the surface quality of the workpiece.

Advantages:

- Maximum stock removal rate.

- Effective chip removal through improved anti-adhesion characteristics.

- Lower thermal loads.Increased tool life.