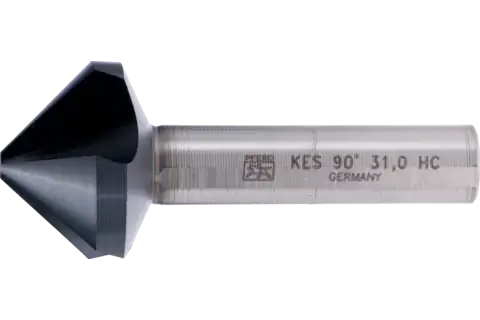

HSS countersink, HICOAT DIN 335 C 90°

HSS conical and deburring countersink 90 ° dia. 31 mm shank dia. 12 mm DIN 335 C HICOAT 3-surface shaft

KES HSS DIN 335 C90° HC-FEP 31,0

Technical information

HSS conical and deburring countersink 90 ° dia. 31 mm shank dia. 12 mm DIN 335 C HICOAT 3-surface shaft

- Angle

- 90 °

- Dia. shank

- 12 mm

- Diameter

- 31 mm

- Length, total

- 71 mm

- RPM, grey cast iron, white cast iron

- 110 - 110 RPM

- RPM, rust and acid-resistant steels

- 110 - 150 RPM

- RPM, soft non-ferrous metals

- 150 - 200 RPM

- RPM, steels up to 700 N/mm²

- 150 - 200 RPM

- RPM, thermoplastics, fibre-reinforced plastics (GRP/CRP)

- 110 - 150 RPM

- Version

- HC-FEP

- Packaging unit

- 1 piece

Description

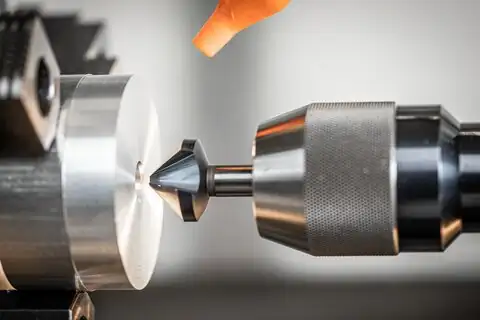

Recommendations for use

Safety notes

- Materials that can be worked

- Applications

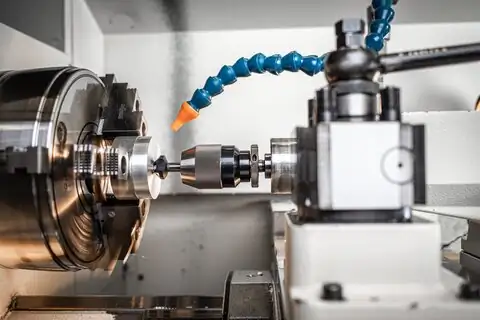

- Drive types