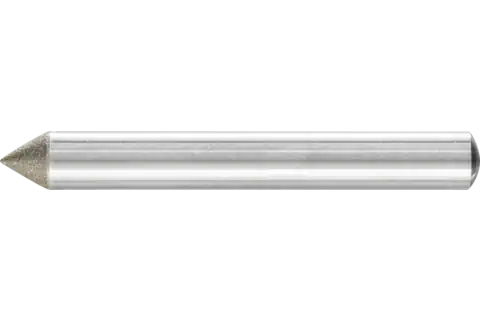

Diamond grinding points conical pointed shape

Diamond grinding point conical pointed dia. 6x60 ° shank dia. 6 mm D64 (fine) for chamfering/deburring/countersinking

DSK 6,0-60°/6 D 64

Technical information

Diamond grinding point conical pointed dia. 6x60 ° shank dia. 6 mm D64 (fine) for chamfering/deburring/countersinking

- Angle

- 60 °

- Dia. external

- 6 mm

- Dia. shank

- 6 mm

- Grit size

- D 64

- Length, shank

- 50 mm

- Width

- 5 mm

- Packaging unit

- 1 piece

Description

Recommendations for use

Ordering notes

- Materials that can be worked

- Applications

- Drive types

PFERD TOOLS VALUE

PFERD TOOLS EFFICIENCY

recommends diamond grinding points for working for long periods with low levels of fatigue, whilst saving resources and achieving perfect results as quickly as possible.

PFERD TOOLS ERGONOMICS

recommends diamond grinding points as an innovative tool solution to sustainably reduce the dust produced during use.