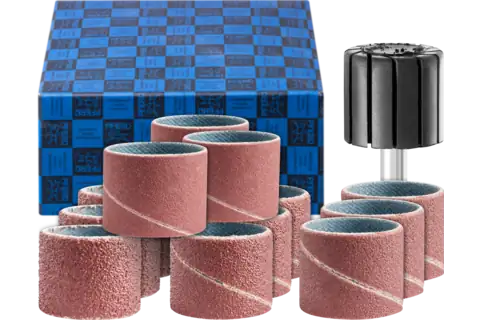

Abrasive spiral band set

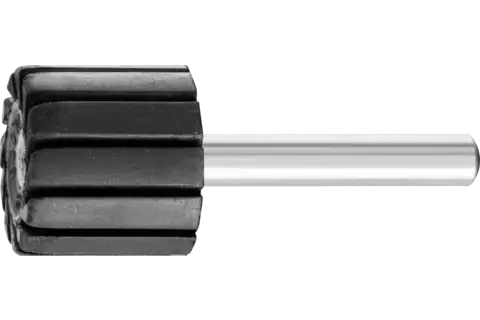

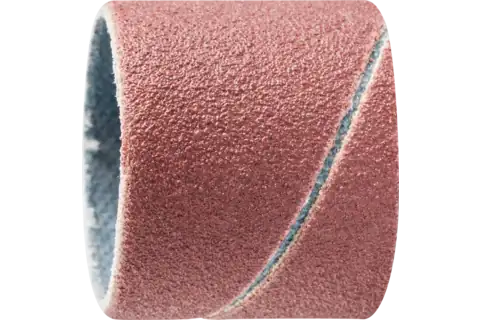

Abrasive spiral band set 13-piece aluminium oxide dia. 22x20 mm A60,80,150,240 with holder shank dia. 6 mm

SET 2220 A

Technical information

Abrasive spiral band set 13-piece aluminium oxide dia. 22x20 mm A60,80,150,240 with holder shank dia. 6 mm

- Dia. external

- 22 mm

- PFERD TOOLS type

- SET 2220 A

- Width

- 20 mm

- Packaging unit

- 1 piece

Description

Advantages

Recommendations for use

Safety notes

- Materials that can be worked

- Applications

- Drive types