Drilling tools

The universal product range for industry and professional trade

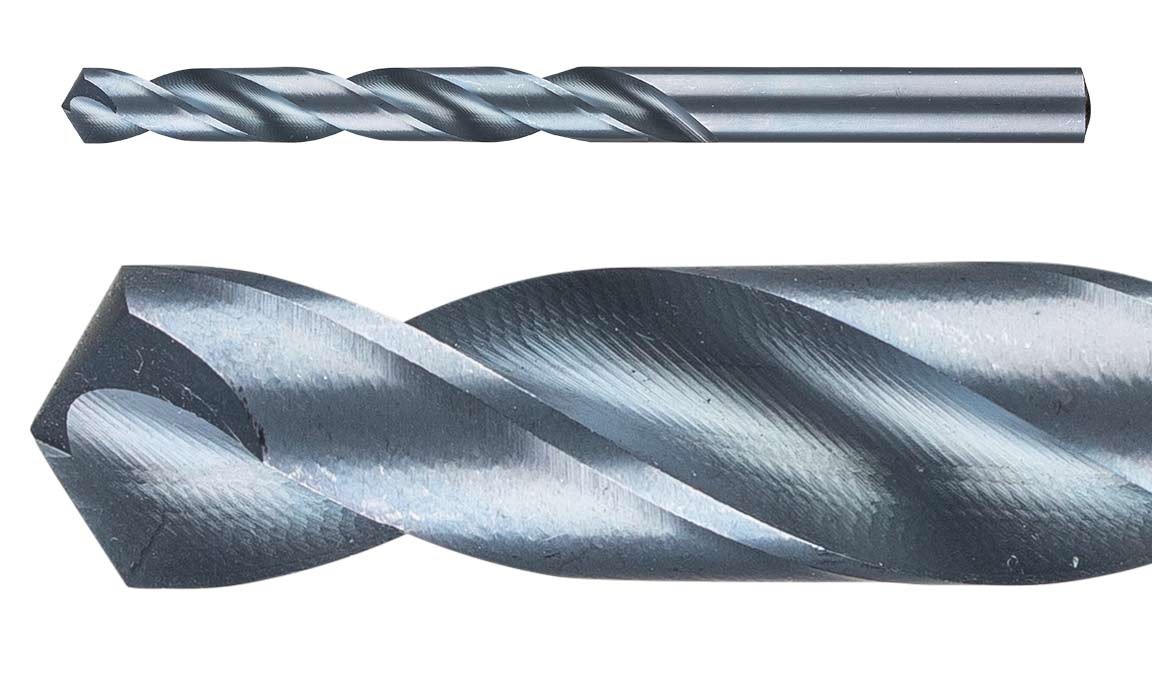

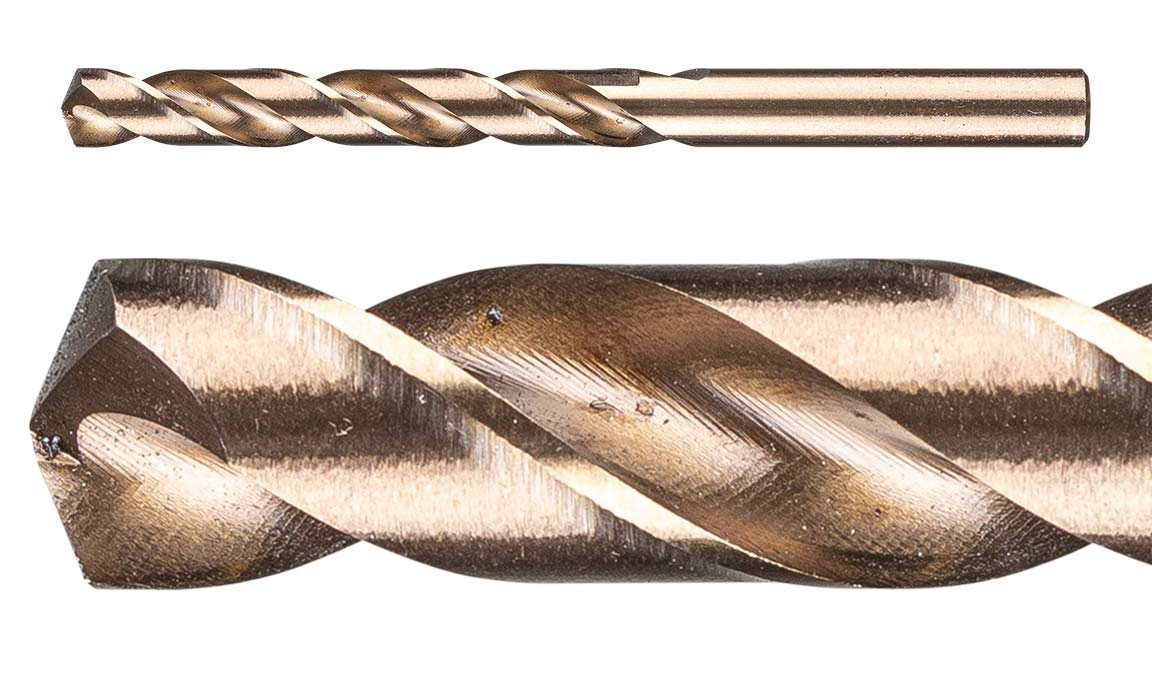

Drilling tools - HSS spiral drills

Drilling tools with cross grinding for industrial uses. Fully ground, right-hand turning versions that produce precise drill holes thanks to their high concentricity and exact centring. PFERD TOOLS offers spiral drills in the STEEL (118° point angle) and INOX (135° point angle) types.

Advantages:

- Very good chip removal.

- High concentricity.

- Exact centring and low feed force thanks to cross grinding.

HSSG (M2) STEEL 118° type

- Suitable for universal use on steel, cast steel, grey cast iron, annealed cast iron, bronze, brass, aluminium.

- Easy centring.

- Long tool life.

- Good chip removal.

HSSE Co5 (M35) INOX 135° type

- Particularly well suited for tough and hard materials, such as alloyed and highstrength steel, stainless steel (INOX).

- Robust tip profile.

- Very long tool life.

- Good chip removal.

- Very good temperature resistance due to Co content.

Drilling tools - HSS step drills

Sturdy high-performance tools for burr-free drilling and deburring of sheet metal, pipes and profiles. Materials up to 4 mm thick can be drilled and deburred easily in a single step. PFERD TOOLS also offers step drills with a high-quality HICOAT coating. To ensure reliable torque transmission, all step drills have a three-surface shaft.

Advantages:

- Drilling and deburring in a single step.

- Completely smooth running and a high cutting performance.

- The high-quality drill tip ensures effortless centring and drilling.

- The tool taper makes it easier to pull back from drilled plates.

- Chips which do not break are neatly removed as with a spiral drill.

- Built-up edges and cold welding on the blades are prevented.

HSS type

Use cutting oil/compressed air as a coolant and lubricant in the case of step drills without a coating.

HSS HICOAT HC-FEP type

- Step drills with a HICOAT coating can also be used without the addition of coolants.

- Particularly suitable for work on stainless steel (INOX).